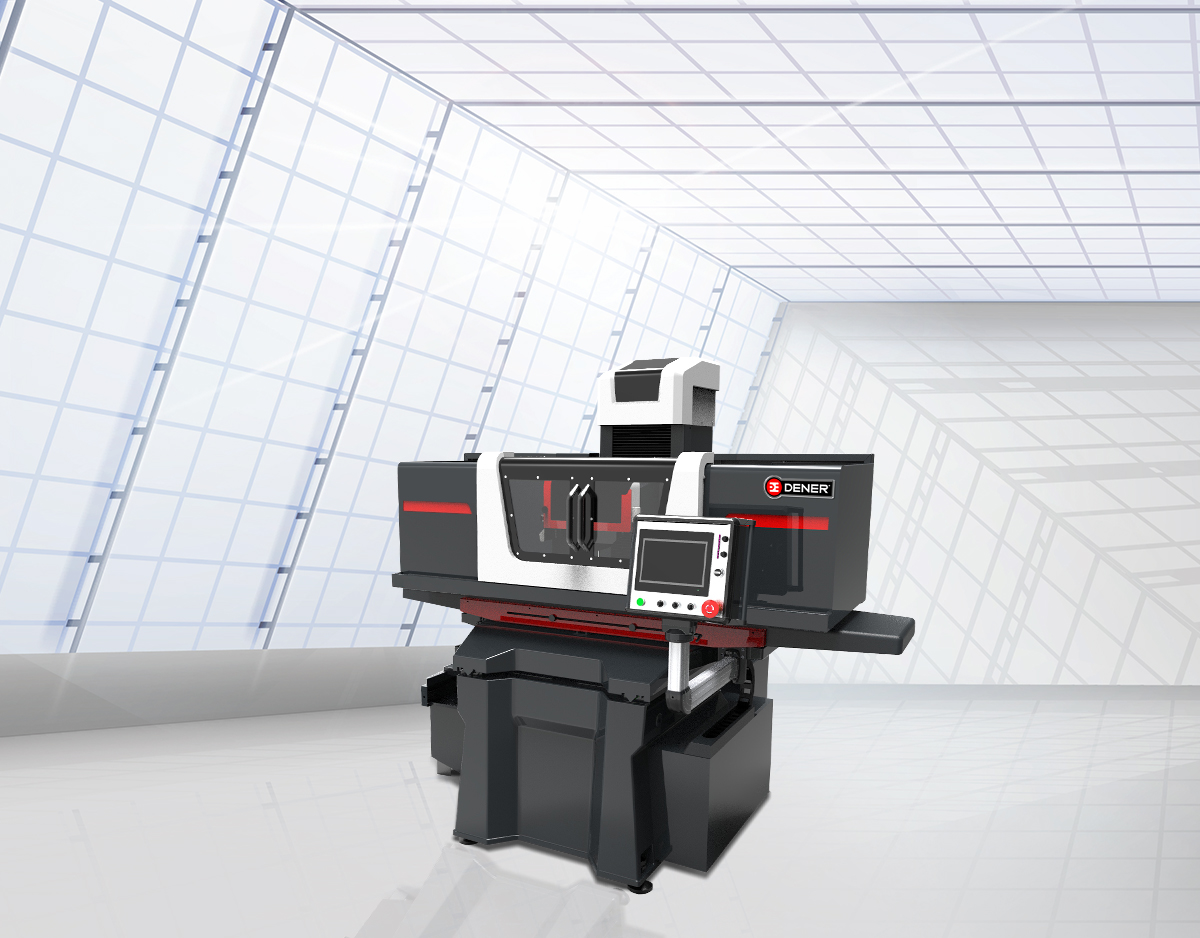

TGH-B 450 NC Grinding Machine

Our high-precision surface grinder machine’s capability to operate with any

kinds of materials for longitudinal and cross directions grinding ensures maximum accuracy.

10” user-friendly touch-screen panel

Vertical and cross travel driven by AC servo motor with ball screw + MPG

Precise chips removal for cross travelling and vertical axis with NC controlling system

Hydraulic system controls for the longitudinal travelling

Ultra-precise, strong, direct-drive without backlash rigid shafts are positioned in multiple locations

V guide-rails, covered with protective casing, provides finer grinding surface finish

Hand-scraped prism box guide-rails provides the finest grinding surface finish

On-time service with spare parts and delivery

| Longitudinal axis movement | 900 | mm |

| Transverse axis movement | 450 | mm |

| Vertical axis movement | 550 | mm |

| Max. Work peace weight | 400 | kg |

| Table Size | 450×900 | mm |

Standard Equipments

Vertical and Cross Feed Driven by AC Servo Motor + MPG

10” Colour LCD Touch-screen Panel

Remote Hand-wheel

Semi Guarding for Table

Grinding Wheel Flange

Electromagnetic Table (400X800)

Wheel Balancing Stand

Balancing Arbor

Grinding Wheel (Ø350xØ127×40)

Puller for Wheel Flange

Table Type Wheel-dresser (With the diamond)

Coolant Equipment

Paper filter cooling equipment (Manual)

Work Light & Program Light

Front door safety switch

Tools & Box

Hydraulic Unit With the Oil (100 Lt)

Chuck Controller for Electromagnetic Table

Lifting Screews

Leveling Bolts & Plates

Operator’s Manual

Optional Equipments

NC controls for vertical and cross axes

Additional wheel flange

Parallel wheel dresser on wheel head (with the diamond)

Sine bar with magnetic (V-S 100M)

Auto paper strip filter with magnetic separator coolant system

Tool maker vice (VMV-40)

Demagnetizer (for work piece) (VDM-68)

Sine bar (VS-100)

Punch former with the sine plate (V-PB-BS)